Mexico was one the major actors in DVA's trade network for global manufacturing exports, during the period under analysis. The automotive industry, while a larger export sector than the textiles, has not followed the same path. However, both industries are considered key players in the export market and are still relevant for job generation in Mexico.

The Mexican automotive industry supplies the United States with the majority of its auto parts. It is also one in the fastest growing industries of Mexico. It has not been capable of bringing the rest on a rapid expansion trajectory. In fact, the automotive industry is undergoing a transition from a domestic-oriented industry to a regional auto parts/automobile chain. This is due to a combination regional processes and foreign direct investments.

Mexico's special programs for development have been a boon to the automotive industry. It has been the top supplier of auto parts in the U.S. and has seen remarkable growth on international markets. It has also benefited from foreign investment, which has been a key factor in its rise in global value chains.

Also, the Mexican automotive industry is a key player within the GVCs of Europe as well as the United States. Mexico's economy has relied heavily on the automotive industry since the 1970s. However, it has not been as well-recognized on the international market as the textile trade. It hasn't seen a lot of growth in its output, but it has had remarkable penetration into international markets.

The study uses the framework of decent work indicators developed by the International Labour Organization (ILO) to analyse the relationship between international trade and labour in the manufacturing sector of Mexico. The indicators are based upon official data and take into account the connections between Mexican labour regulations and trade agreements. Input-output analysis is part of the international trade indicators. It shows that Mexico plays an insignificant role in the global value-added to manufacturing exports.

The study also analyzes the impact of trade liberalization on the employment situation in Mexico's manufacturing sector. The System of National Accounts Framework (SNA) framework is used to establish a set of decent job indicators for two major industrial sectors in Mexico, transport equipment and textiles. These indicators are constructed over time and used to evaluate the development of decent work in Mexico. The study finds that the level of D V A G V C in the manufacturing sector is considerably lower than in the textile sector. Similar to the textile sector, the study shows that the level in which the employment in automotive is higher than the textile sector's is also lower. The study also finds that real wages have decreased since the beginning. In other words, the nominal wage adjustment was not enough to compensate for the deterioration of real wages. The study shows that DVA in exports for transport equipment has increased in recent years, while DVA has decreased in exports for textiles.

FAQ

What's the difference between Production Planning & Scheduling?

Production Planning (PP), also known as forecasting and identifying production capacities, is the process that determines what product needs to be produced at any particular time. Forecasting demand is one way to do this.

Scheduling involves the assignment of dates and times to tasks in order to complete them within the timeframe.

How does a production planner differ from a project manager?

The major difference between a Production Planner and a Project Manager is that a Project Manager is often the person responsible for organizing and planning the entire project. While a Production Planner is involved mainly in the planning stage,

What is production plan?

Production Planning involves developing a plan for all aspects of the production, including scheduling, budgeting, casting, crew, location, equipment, props, etc. This document is designed to make sure everything is ready for when you're ready to shoot. It should also contain information on achieving the best results on set. This includes location information, crew details, equipment specifications, and casting lists.

The first step is to decide what you want. You might have an idea of where you want to film, or you may have specific locations or sets in mind. Once you have identified your locations and scenes, you can start working out which elements you require for each scene. One example is if you are unsure of the exact model you want but decide that you require a car. In this case, you could start looking up cars online to find out what models are available and then narrow your choices by choosing between different makes and models.

Once you have found the right vehicle, you can think about adding accessories. What about additional seating? Or maybe you just need someone to push the car around. Maybe you'd like to change the interior from black to a white color. These questions will help you determine the exact look and feel of your car. You can also think about the type of shots you want to get. Will you be filming close-ups or wide angles? Maybe you want the engine or the steering wheels to be shown. These details will help identify the exact car you wish to film.

Once you have established all the details, you can create a schedule. The schedule will show you when to begin shooting and when to stop. A schedule for each day will detail when you should arrive at the location and when you need leave. Everyone will know what they need and when. Book extra staff ahead of time if you need them. You should not hire anyone who doesn't show up because of your inaction.

When creating your schedule, you will also need to consider the number of days you need to film. Some projects can be completed in a matter of days or weeks. Others may take several days. It is important to consider whether you require more than one photo per day when you create your schedule. Multiple takes at the same place will result in higher costs and longer completion times. It is better to be cautious and take fewer shots than you risk losing money if you are not sure if multiple takes are necessary.

Budgeting is another crucial aspect of production plan. As it will allow you and your team to work within your financial means, setting a realistic budget is crucial. Keep in mind that you can always reduce your budget if you face unexpected difficulties. However, you shouldn't overestimate the amount of money you will spend. If you underestimate how much something costs, you'll have less money to pay for other items.

Planning production is a tedious process. Once you have a good understanding of how everything works together, planning future projects becomes easy.

Statistics

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

How to Use 5S to Increase Productivity in Manufacturing

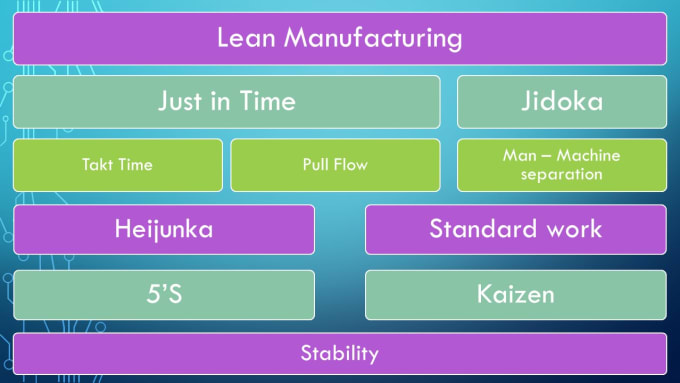

5S stands in for "Sort", the "Set In Order", "Standardize", or "Separate". Toyota Motor Corporation invented the 5S strategy in 1954. It improves the work environment and helps companies to achieve greater efficiency.

The idea behind standardizing production processes is to make them repeatable and measurable. It means tasks like cleaning, sorting or packing, labeling, and storing are done every day. Through these actions, workers can perform their jobs more efficiently because they know what to expect from them.

There are five steps to implementing 5S, including Sort, Set In Order, Standardize, Separate and Store. Each step involves a different action which leads to increased efficiency. By sorting, for example, you make it easy to find the items later. You arrange items by placing them in an order. You then organize your inventory in groups. Labeling your containers will ensure that everything is correctly labeled.

This process requires employees to think critically about how they do their job. Employees need to be able understand their motivations and discover alternative ways to do them. In order to use the 5S system effectively, they must be able to learn new skills.

The 5S Method not only improves efficiency, but it also helps employees to be more productive and happier. They will feel motivated to strive for higher levels of efficiency once they start to see results.