You need the right qualifications to pursue a career in maintenance engineering. Here are some of these certifications and the expected earnings. The job of a maintenance engineer is a great fit for people with an eye for detail. These professionals are responsible in maintaining and optimizing a building’s infrastructure.

Qualifications needed to become a maintenance engineer

Here are some key points to remember if you are interested in a career of maintenance engineer. While a highschool diploma will provide you with the foundational skills needed, you might also be interested in taking an engineering course at college. It will be beneficial to take courses in chemistry and math. You can also gain work experience. A technical school may be an option depending on the needs and interests of your company.

Maintenance engineers are responsible to maintain machinery and equipment. Their job is to keep industrial machinery operating as efficiently as possible. They also manage the supply of spare part and supplies. Many jobs in this industry require work hours, especially those in manufacturing. Maintenance engineers can move up to managerial positions depending on their work. They may also pursue other jobs in the same industry. Once they have accumulated experience, they can even go into business for themselves.

Maintenance engineers can earn an average salary of PS20,000 to PS25,000. Salaries can vary depending on the size and industry of the organization. Management positions require leadership skills and maintenance engineers can move on to higher levels. You may also be able to achieve Chartered status, which can help you move up in your career.

Certifications are required

A variety of certifications may be required for maintenance engineers. These certifications can be specific to one system or may relate to hazardous material handling. The International Maintenance Institute offers several levels of professional certification. These include certified maintenance technicians at lower levels, and maintenance managers at higher levels.

First, consider your education if you're interested to become a maintenance engineering engineer. Most certification companies don't require a specific education, but some recommend having a high-school diploma or GED. Most employers and recruiters require this minimum qualification. However, you can also obtain a certification without a degree if you've had previous work experience in a similar industry.

While a bachelor's is not necessary to become a maintenance engineering professional, a degree that's relevant will help you stand apart from the crowd. An engineering degree in mechanical engineering, electrical engineering or facilities management might be helpful. Even if your degree is not in engineering, you might be able find work as a maintenance technician. You can also work your way up to the maintenance engineer level with experience and training.

Salary

The Bureau of Labor Statistics cannot monitor the salary of maintenance technicians, but they do project that there will be job growth in similar fields. General maintenance workers and mechanical engineers will see a 8% increase, while construction managers could see an 11% increase in employment. Consider a career for maintenance engineers if you're interested in this job. You can either look for entry-level or high-growth jobs in these industries.

Maintenance engineer salaries: The median 2008 salary for maintenance engineers stood at $88,570. The lowest 25 % earned $48,270, and the highest 10 % earned more that $110,310.

FAQ

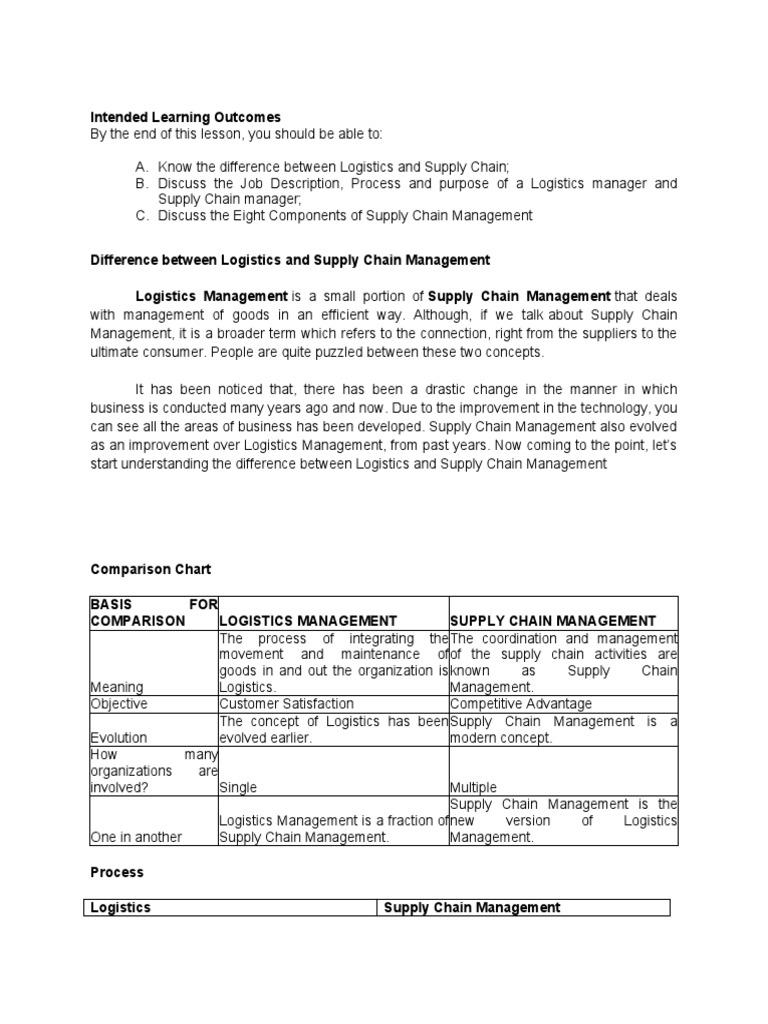

What does manufacturing mean?

Manufacturing Industries refers to businesses that manufacture products. Consumers are the people who purchase these products. This is accomplished by using a variety of processes, including production, distribution and retailing. They produce goods from raw materials by using machines and other machinery. This includes all types of manufactured goods, including food items, clothing, building supplies, furniture, toys, electronics, tools, machinery, vehicles, pharmaceuticals, medical devices, chemicals, and many others.

What are the four types in manufacturing?

Manufacturing is the process by which raw materials are transformed into useful products through machines and processes. It includes many different activities like designing, building and testing, packaging, shipping and selling, as well as servicing.

What are manufacturing & logistics?

Manufacturing refers the process of producing goods from raw materials through machines and processes. Logistics covers all aspects involved in managing supply chains, including procurement and production planning. Logistics and manufacturing are often referred to as one thing. It encompasses both the creation of products and their delivery to customers.

Statistics

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

External Links

How To

How to use lean manufacturing in the production of goods

Lean manufacturing refers to a method of managing that seeks to improve efficiency and decrease waste. It was developed by Taiichi Okono in Japan, during the 1970s & 1980s. TPS founder Kanji Takoda awarded him the Toyota Production System Award (TPS). Michael L. Watkins published the book "The Machine That Changed the World", which was the first to be published about lean manufacturing.

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It emphasizes the elimination of defects and waste throughout the value stream. Lean manufacturing can be described as just-in–time (JIT), total productive maintenance, zero defect (TPM), or even 5S. Lean manufacturing emphasizes reducing non-value-added activities like inspection, rework and waiting.

Lean manufacturing is a way for companies to achieve their goals faster, improve product quality, and lower costs. Lean manufacturing has been deemed one of the best ways to manage the entire value-chain, including customers, distributors as well retailers and employees. Lean manufacturing practices are widespread in many industries. Toyota's philosophy has been a key driver of success in many industries, including automobiles and electronics.

Five fundamental principles underlie lean manufacturing.

-

Define Value: Identify the social value of your business and what sets you apart.

-

Reduce Waste - Eliminate any activity that doesn't add value along the supply chain.

-

Create Flow – Ensure that work flows smoothly throughout the process.

-

Standardize and Simplify – Make processes as consistent, repeatable, and as simple as possible.

-

Build relationships - Develop and maintain personal relationships with both your internal and external stakeholders.

Lean manufacturing isn’t new, but it has seen a renewed interest since 2008 due to the global financial crisis. Many businesses are now using lean manufacturing to improve their competitiveness. In fact, some economists believe that lean manufacturing will be an important factor in economic recovery.

Lean manufacturing is now becoming a common practice in the automotive industry, with many benefits. These benefits include increased customer satisfaction, reduced inventory levels and lower operating costs.

Any aspect of an enterprise can benefit from Lean manufacturing. This is because it ensures efficiency and effectiveness in all stages of the value chain.

There are three main types of lean manufacturing:

-

Just-in-Time Manufacturing: Also known as "pull systems", this type of lean manufacturing uses just-in-time manufacturing (JIT). JIT means that components are assembled at the time of use and not manufactured in advance. This approach reduces lead time, increases availability and reduces inventory.

-

Zero Defects Manufacturing, (ZDM): ZDM is focused on ensuring that no defective products leave the manufacturing facility. You should repair any part that needs to be repaired during an assembly line. This also applies to finished products that need minor repairs before being shipped.

-

Continuous Improvement (CI: Continuous improvement aims to increase the efficiency of operations by constantly identifying and making improvements to reduce or eliminate waste. It involves continuous improvement of processes, people, and tools.