The Department of Energy, a federal agency, is responsible for managing the United States' nuclear facilities and energy policy. They also supervise scientific research in energy and environmental matters. Below is a list of some of their programs. The Office of Fossil Energy develops policy on the use of natural gas, coal, and electric energy. The Nuclear Weapons Program oversees nuclear reactor production for the United States Navy. Listed below are some of the programs within the Department of Energy.

The Office of Fossil Energy creates policies regarding the use of natural gas and coal.

The Department of the Interior includes the Office of Fossil Energy. This office is responsible in part for policies related to the consumption of natural gas, electricity, and coal. The OFE creates and directs projects to improve energy efficiency. It also works to reduce the pollution caused by existing power plants. This is a major contributor to global warming. Fossil fuels are responsible for approximately 85% our country's electricity supply. The OFE works towards limiting their use.

Office of Energy Research pioneered research projects and facilities projects

The Office of Energy Research has been a leader in research and facilities projects within the Department of Energy. It was responsible to create the Human Genome Project, Global Climate Change Program, as well as many other large-scale research centers. The Office has a long track record in accelerator science. It has built many large particle colliders and x-ray synchrotron lights sources as well as fusion experiments.

Office of Nuclear Weapons Policy has policies to govern the use of nuclear weapons

The Office of Nuclear Weapons Policy in the Department of Energy is responsible for developing policies relating to nuclear weapons. Its main task is to develop and evaluate nuclear weapons policies. Nuclear weapons can be dangerous, so it is crucial to make sure they are not used. Some analysts have raised concerns about the plans of the administration and have also raised their own questions. Some critics doubt the necessity for over 2200 warheads in deployed forces. Others claim Russia is the only antagonist with sufficient targets to justify broad-spread attacks against its nuclear weapons.

Nuclear weapons program oversees U.S. nuclear reactor production for the United States Navy

Many components are part of the U.S. Nuclear Weapons Program. Many of these components support other military missions. The U.S. Strategic Bomber is an example of a vital conventional mission. However, it does not fly with nuclear weapons and does not carry out airborne alert. Also, the first quick-reaction strip was not available for strategic bombers until the early 1990s. The U.S. still has a large stockpile of nukes.

Since 1990, Office of Energy Research is on the Government Accountability Office High Risk List

The Department of Energy has had to go through a difficult and long road to restore trust since its inclusion on this list. GAO has worked to improve the performance and public service of the Department of Energy by addressing the issues that cause it to fall short. Some areas have been removed, but others are still high-risk. Here's a brief summary of what the new High-Risk Report identifies as the most pressing issues facing the government today.

FAQ

What is the difference between Production Planning and Scheduling?

Production Planning (PP), or production planning, is the process by which you determine what products are needed at any given time. Forecasting demand is one way to do this.

Scheduling refers to the process of allocating specific dates to tasks in order that they can be completed within a specified timeframe.

What is the role of a production manager?

Production planners ensure all aspects of the project are delivered within time and budget. A production planner ensures that the service and product meet the client's expectations.

Is automation necessary in manufacturing?

Not only are service providers and manufacturers important, but so is automation. It enables them to provide services faster and more efficiently. It reduces human errors and improves productivity, which in turn helps them lower their costs.

What is manufacturing and logistics?

Manufacturing is the act of producing goods from raw materials using machines and processes. Logistics encompasses the management of all aspects associated with supply chain activities such as procurement, production planning, distribution and inventory control. It also includes customer service. Logistics and manufacturing are often referred to as one thing. It encompasses both the creation of products and their delivery to customers.

Is it necessary to be familiar with Manufacturing Processes before we learn about Logistics.

No. You don't have to know about manufacturing processes before learning about logistics. Understanding the manufacturing process will allow you to better understand logistics.

Why is logistics so important in manufacturing?

Logistics are an essential component of any business. Logistics can help you achieve amazing results by helping to manage product flow from raw materials to finished products.

Logistics play an important role in reducing costs as well as increasing efficiency.

What are the responsibilities of a manufacturing manager

The manufacturing manager should ensure that every manufacturing process is efficient and effective. They should be aware of any issues within the company and respond accordingly.

They should also learn how to communicate effectively with other departments, including sales and marketing.

They should also be knowledgeable about the latest trends in the industry so they can use this information for productivity and efficiency improvements.

Statistics

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

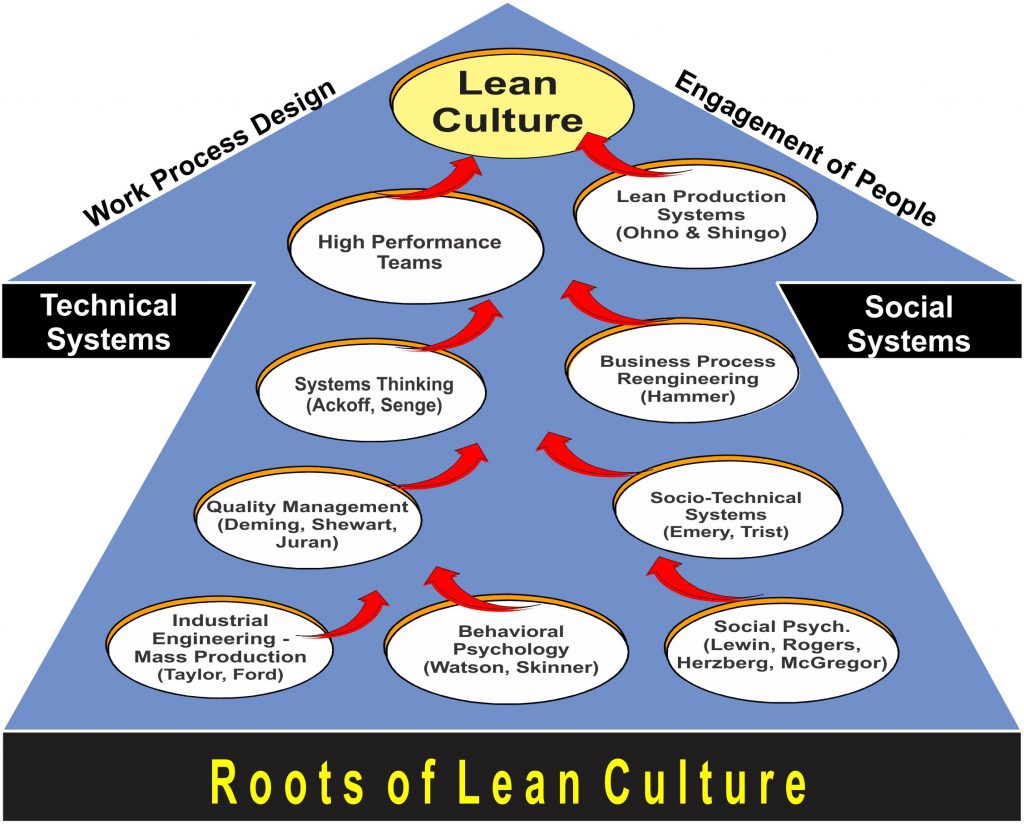

Six Sigma and Manufacturing

Six Sigma refers to "the application and control of statistical processes (SPC) techniques in order to achieve continuous improvement." Motorola's Quality Improvement Department developed it at their Tokyo plant in Japan in 1986. Six Sigma is a method to improve quality through standardization and elimination of defects. Since there are no perfect products, or services, this approach has been adopted by many companies over the years. Six Sigma seeks to reduce variation between the mean production value. This means that if you take a sample of your product, then measure its performance against the average, you can find out what percentage of the time the process deviates from the norm. If this deviation is too big, you know something needs fixing.

Understanding the nature of variability in your business is the first step to Six Sigma. Once you have a good understanding of the basics, you can identify potential sources of variation. Also, you will need to identify the sources of variation. Random variations are caused by human errors. Systematic variations can be caused by outside factors. Random variations would include, for example, the failure of some widgets to fall from the assembly line. You might notice that your widgets always fall apart at the same place every time you put them together.

Once you have identified the problem, you can design solutions. The solution could involve changing how you do things, or redesigning your entire process. Once you have implemented the changes, it is important to test them again to ensure they work. If they didn't work, then you'll need to go back to the drawing board and come up with another plan.