The job of an industrial engineer is to create and implement processes that reduce wastefulness and maximize resource use. These engineers work in a range of industries to design processes that can benefit their company in a variety. They analyze production schedules, design specifications, workflows, and other factors to improve the efficiency of company processes. Industrial engineers also analyze the production process efficiency to increase profitability. They also contribute to improving the quality of services and products.

Requirements for an industrial engineer

An Industrial Engineer plays a crucial role in a manufacturing organization by utilizing innovative design systems to deliver streamlined operations for the natural and organic food industries. This individual develops innovative solutions for internal customers and manages dynamic projects to improve the manufacturing process. This job requires that an individual is able and qualified to perform all of the essential tasks. Industrial engineers must be familiar with AutoCAD and Pro-E, and they must be knowledgeable of advanced product quality planning and the production part approval process.

Industrial Engineers are responsible for designing and testing efficient integrated systems. Other than this, the job requires an understanding of human work factors and product quality to ensure maximum efficiency. Other responsibilities include cost analysis and guest coordination. In addition, this person must be proficient in advanced technical skills such as Microsoft Office. You will also need experience in logistics, manufacturing, and systems design. In Orlando, you must have the technical skills necessary to perform your job well.

Salary for industrial engineer

You should look at the salaries for Industrial & Manufacturing Engineers here in Orlando, FL if you are considering a career in this field. Orlando is one the best places in America, with an average annual salary of $803,325 This salary is 6% lower that the national average. It's also 9% lower than New York's average salary. Orlando's median salary range is $64,260 - $96,390. With the middle 67% earning $85,000 annually and the top 10% earning $102,000, the average Orlando worker earns $64,260.

Industrial Engineers can earn salaries ranging from $89,700 to $114,300 USD. Industrial engineers can earn a variety of salaries, just like other careers. The above salary figures represent the average income for an Industrial Engineer who has five to ten-years of experience. However, the average salary for an Industrial Engineer with five to ten years of experience is almost double that of someone with less experience. The exact pay scales for different industrial engineers are not the same.

Industrial engineer responsibilities

As a process designer and manager, you will determine the best ways to improve process performance. To meet customer needs and achieve business goals, you will need to create and implement flexible and efficient processes. The Industrial Engineer may be required to perform many tasks. They could include Cost Analysis, Capacity Planning or Reporting. Capital Project Management is also possible. Discrete event simulation is another example. It is also expected that you will perform time studies, observations, and contribute to cross-functional improvement efforts.

Strong communication skills are required, as well as engineering experience and a strong grasp of statistical analysis, to be able do this job. Managers will be closely involved in the development of design standards for industrial engineers and leading moderately difficult projects. They will use data analysis to create statistical reports that can improve process flow, time and quality. They will coordinate key studies, produce key metric reports, and process documentation.

FAQ

Do we need to know about Manufacturing Processes before learning about Logistics?

No. You don't have to know about manufacturing processes before learning about logistics. It is important to know about the manufacturing processes in order to understand how logistics works.

Is automation important for manufacturing?

Not only is automation important for manufacturers, but it's also vital for service providers. It enables them to provide services faster and more efficiently. It helps them to lower costs by reducing human errors, and improving productivity.

What is production planning?

Production Planning is the creation of a plan to cover all aspects, such as scheduling, budgeting. Location, crew, equipment, props and other details. It is important to have everything ready and planned before you start shooting. It should also provide information about how best to produce the best results while on set. This includes information on shooting times, locations, cast lists and crew details.

It is important to first outline the type of film you would like to make. You may already know where you want the film to be shot, or perhaps you have specific locations and sets you wish to use. Once you have identified your locations and scenes it's time to begin figuring out what elements you will need for each one. For example, you might decide that you need a car but don't know exactly what model you want. To narrow your options, you can search online for available models.

After you've found the perfect car, it's time to start thinking about adding extras. Do you need people sitting in the front seats? Perhaps you have someone who needs to be able to walk around the back of your car. Perhaps you would like to change the interior colour from black to white. These questions will help guide you in determining the ideal look and feel for your car. You can also think about the type of shots you want to get. What type of shots will you choose? Maybe you want to show your engine or the steering wheel. This will allow you to determine the type of car you want.

Once you've determined the above, it is time to start creating a calendar. A schedule will tell you when you need to start shooting and when you need to finish. The schedule will show you when to get there, what time to leave, and when to return home. So everyone is clear about what they need to do. Book extra staff ahead of time if you need them. You don't want to hire someone who won't show up because he didn't know.

Your schedule will also have to be adjusted to reflect the number of days required to film. Some projects may only take a couple of days, while others could last for weeks. When you are creating your schedule, you should always keep in mind whether you need more than one shot per day or not. Shooting multiple takes over the same location will increase costs and take longer to complete. It's better to be safe than sorry and shoot less takes if you're not certain whether you need more takes.

Another important aspect of production planning is setting budgets. You will be able to manage your resources if you have a realistic budget. Remember that you can always reduce the budget later on if you run into unforeseen problems. However, it is important not to overestimate the amount that you will spend. You will end up spending less money if you underestimate the cost of something.

Production planning is a very detailed process, but once you understand how everything works together, it becomes easier to plan future projects.

What is manufacturing and logistics?

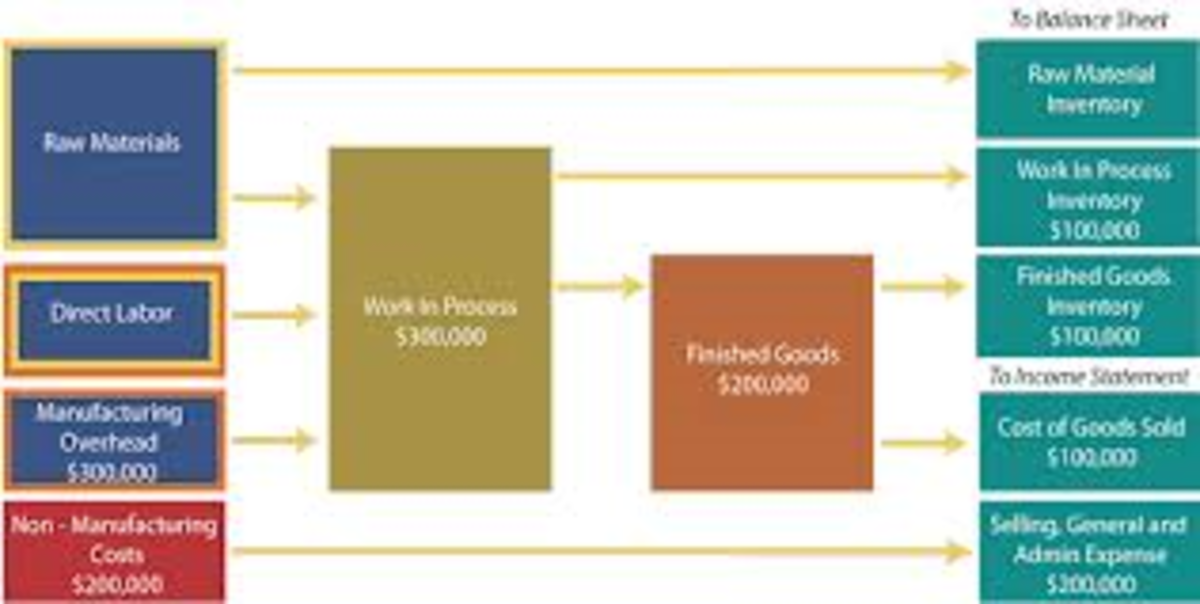

Manufacturing refers to the process of making goods using raw materials and machines. Logistics is the management of all aspects of supply chain activities, including procurement, production planning, distribution, warehousing, inventory control, transportation, and customer service. Sometimes manufacturing and logistics are combined to refer to a wider term that includes both the process of creating products as well as their delivery to customers.

What are the responsibilities of a manufacturing manager

A manufacturing manager must ensure that all manufacturing processes are efficient and effective. They should be aware of any issues within the company and respond accordingly.

They should also learn how to communicate effectively with other departments, including sales and marketing.

They must also keep up-to-date with the latest trends in their field and be able use this information to improve productivity and efficiency.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

How to Use Just-In-Time Production

Just-in-time (JIT) is a method that is used to reduce costs and maximize efficiency in business processes. It's the process of obtaining the right amount and timing of resources when you need them. This means that your only pay for the resources you actually use. Frederick Taylor first coined this term while working in the early 1900s as a foreman. He saw how overtime was paid to workers for work that was delayed. He realized that workers should have enough time to complete their jobs before they begin work. This would help increase productivity.

JIT is an acronym that means you need to plan ahead so you don’t waste your money. Look at your entire project, from start to end. Make sure you have enough resources in place to deal with any unexpected problems. If you anticipate that there might be problems, you'll have enough people and equipment to fix them. This will prevent you from spending extra money on unnecessary things.

There are many types of JIT methods.

-

Demand-driven JIT: This is a JIT that allows you to regularly order the parts/materials necessary for your project. This will allow for you to track the material that you have left after using it. This will allow you to calculate how long it will take to make more.

-

Inventory-based : You can stock the materials you need in advance. This allows you to predict how much you can expect to sell.

-

Project-driven : This is a method where you make sure that enough money is set aside to pay the project's cost. If you know the amount you require, you can buy the materials you need.

-

Resource-based: This is the most common form of JIT. This is where you assign resources based upon demand. For example, if there is a lot of work coming in, you will have more people assigned to them. If there aren't many orders, you will assign fewer people.

-

Cost-based : This is similar in concept to resource-based. But here, you aren't concerned about how many people your company has but how much each individual costs.

-

Price-based pricing: This is similar in concept to cost-based but instead you look at how much each worker costs, it looks at the overall company's price.

-

Material-based - This is a variant of cost-based. But instead of looking at the total company cost, you focus on how much raw material you spend per year.

-

Time-based JIT: A variation on resource-based JIT. Instead of focusing on the cost of each employee, you will focus on the time it takes to complete a project.

-

Quality-based JIT - This is another form of resource-based JIT. Instead of looking at the labor costs and time it takes to make a product, think about its quality.

-

Value-based JIT: One of the most recent forms of JIT. This is where you don't care about how the products perform or whether they meet customers' expectations. Instead, you focus on the added value that you provide to your market.

-

Stock-based is an inventory-based system that measures the number of items produced at any given moment. This method is useful when you want to increase production while decreasing inventory.

-

Just-in-time (JIT) planning: This is a combination of JIT and supply chain management. It refers to the process of scheduling the delivery of components as soon as they are ordered. It's important because it reduces lead times and increases throughput.