Facilities engineers, also known as maintenance and engineering engineers, provide engineering and support services for buildings and operations. Some of their duties include developing and implementing procedures, recommending repair and upgrades, and coordinating routine and emergency maintenance. Their role can involve a wide variety of engineering disciplines, including mechanical, electrical, and plumbing. Aside from their technical expertise, they have a good understanding of construction law, safety standards and other regulatory requirements.

Facilities engineers can start at the entry-level and quickly move up to more senior roles. You can stand out in your field by building a strong portfolio. This may include projects, research, or articles. Additionally, facilities engineers should continue to learn about their specialty. This will allow them to stand out when applying to a new position.

Although it is not mandatory for all facilities engineers, a professional engineer certification can be a big advantage when applying for a new position. A professional engineer should possess a broad knowledge of engineering principles and concepts, as well as the ability to analyze data and make compelling presentations. Facility engineers should be familiar with asset reliability-centered maintenance strategies and predictive maintenance.

Typical jobs for facility engineers are in office, construction, or manufacturing settings. They manage and implement processes that ensure safe, efficient, effective, and reliable operation of utility systems. Facilities engineers often work closely alongside other engineers and managers, helping to create efficient work routines and deal with any issues that might arise.

A facilities engineer's responsibilities will vary based on the size and type of facility he or she is assigned to work in. This job requires excellent problem-solving and time management skills. During a typical day, a facilities engineer may perform hundreds of tasks. A facilities engineer may be responsible for mechanical, electrical, or plumbing equipment. They must also be able troubleshoot problems and fix them.

Many websites offer information and news about the field, including the Association of Facility Engineers' (AFE) website. These websites contain information about the profession, including a sample resume.

You can also find articles and books on facilities engineering, as well as training courses and networking opportunities. A successful facilities engineer will have good organizational skills, an excellent understanding of construction and engineering disciplines, as well as a solid knowledge of safety codes and building regulations.

It is important to remember that even the most skilled facilities engineers can analyze data and complete multiple tasks simultaneously. These engineers need to have a working knowledge of AutoCAD design software and construction techniques like the CAM method. You will also benefit from skills such as project management, critical thinking and problem solving.

One of the best things about a job in facilities engineering is the opportunity to work closely with a diverse group of people. Many of these engineers have been trained to work with a wide range of materials and can coordinate work from other engineers.

FAQ

What does warehouse refer to?

Warehouses and storage facilities are where goods are kept before being sold. It can be an indoor space or an outdoor area. It could be one or both.

What is the responsibility of a production planner?

A production planner makes sure all project elements are delivered on schedule, within budget, as well as within the agreed scope. A production planner ensures that the service and product meet the client's expectations.

What skills does a production planner need?

Being a production planner is not easy. You need to be organized and flexible. It is also important to be able communicate with colleagues and clients.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

How to use Lean Manufacturing in the production of goods

Lean manufacturing is a management system that aims at increasing efficiency and reducing waste. It was developed in Japan during the 1970s and 1980s by Taiichi Ohno, who received the Toyota Production System (TPS) award from TPS founder Kanji Toyoda. Michael L. Watkins published the original book on lean manufacturing, "The Machine That Changed the World," in 1990.

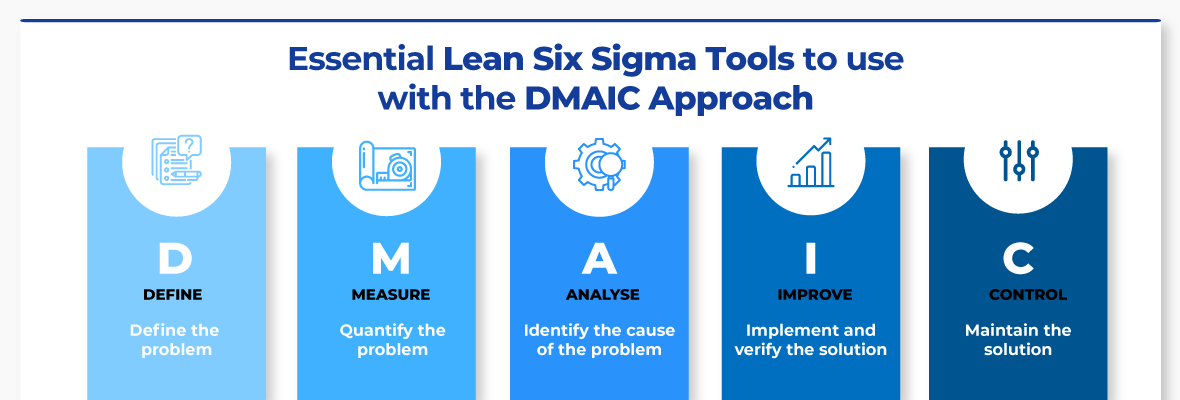

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It emphasizes reducing defects and eliminating waste throughout the value chain. Lean manufacturing can be described as just-in–time (JIT), total productive maintenance, zero defect (TPM), or even 5S. Lean manufacturing emphasizes reducing non-value-added activities like inspection, rework and waiting.

Lean manufacturing can help companies improve their product quality and reduce costs. Additionally, it helps them achieve their goals more quickly and reduces employee turnover. Lean manufacturing has been deemed one of the best ways to manage the entire value-chain, including customers, distributors as well retailers and employees. Lean manufacturing practices are widespread in many industries. Toyota's philosophy is a great example of this. It has helped to create success in automobiles as well electronics, appliances and healthcare.

Lean manufacturing is based on five principles:

-

Define Value - Determine the value that your business brings to society. Also, identify what sets you apart from your competitors.

-

Reduce Waste - Eliminate any activity that doesn't add value along the supply chain.

-

Create Flow. Ensure that your work is uninterrupted and flows seamlessly.

-

Standardize and simplify - Make your processes as consistent as possible.

-

Build Relationships - Establish personal relationships with both internal and external stakeholders.

Although lean manufacturing isn't a new concept in business, it has gained popularity due to renewed interest in the economy after the 2008 global financial crisis. Many companies have adopted lean manufacturing methods to increase their marketability. According to some economists, lean manufacturing could be a significant factor in the economic recovery.

Lean manufacturing has many benefits in the automotive sector. These include higher customer satisfaction levels, reduced inventory levels as well as lower operating costs.

Lean manufacturing can be applied to almost every aspect of an organization. This is because it ensures efficiency and effectiveness in all stages of the value chain.

There are three types principally of lean manufacturing:

-

Just-in Time Manufacturing, (JIT): This kind of lean manufacturing is also commonly known as "pull-systems." JIT stands for a system where components are assembled on the spot rather than being made in advance. This approach reduces lead time, increases availability and reduces inventory.

-

Zero Defects Manufacturing: ZDM ensures that no defective units leave the manufacturing plant. It is better to repair a part than have it removed from the production line if it needs to be fixed. This applies to finished products, which may need minor repairs before they are shipped.

-

Continuous Improvement (CI), also known as Continuous Improvement, aims at improving the efficiency of operations through continuous identification and improvement to minimize or eliminate waste. Continuous improvement involves continuous improvement of processes and people as well as tools.