Companies that use advanced manufacturing technology to improve their products and processes often incorporate new technologies. These technologies can be described as innovative, cutting edge and advanced. More companies are integrating these technologies into their operations. These technologies include robotics, material deposition and additive manufacturing. Learn more about these technologies.

Additive manufacturing

Advanced manufacturing through additive manufacturing is the future for many manufacturing businesses. This type of manufacturing uses additive manufacturing technologies (also known as 3D printing). This type of manufacturing has several advantages, including increased flexibility and lower inventory costs. This type of manufacturing also makes it less costly to import labor-intensive parts or components.

Innovations in additive manufacturing technology have greatly increased the speed of manufacturing. They allow companies to quickly respond to supply chain disruptions. They can create custom parts in a matter of hours, or even days. This process is especially valuable in industries that experience supply-chain problems. Advanced manufacturing is capable of producing parts with complex geometries.

Manufacturers can also produce very small quantities. This can be used, for example, to create custom dental appliances. The process can also be used to create complex structures such as internal heat channels. Advanced manufacturing by additive manufacturing can also be used to reduce inventory and create specialized parts. It can reduce materials costs up to ninety percent while reducing energy consumption by as much as half.

Robotics

Most industrial producers have recognized the potential for advanced robotics and are looking to implement them in their factories. They aren't satisfied with the current performance and progress made in their implementation. They cite high technology's limitations and high costs as obstacles to wider deployment. They lack the necessary enablers to fully implement advanced robotics in their plants.

In order to successfully integrate advanced robots, manufacturers must examine their system architecture. These systems should include infrastructure, analytics, data management, workflow management, and data storage. After these capabilities are established, companies can select strategic robotics vendors. These partners will be able to help the company choose which processes and technologies are most suitable for their business. For robotics, simulation models are useful.

Numerous industries are seeing rapid growth in the use of advanced robotics. Robotic automation can be applied in many areas, such as aerospace, medical and automotive manufacturing. This technology has made manufacturing more efficient. Advanced robotic automation not only reduces labor costs but also saves energy because it works 24 hours a days and doesn't require lights.

Material deposition

Material deposition is a crucial technique in advanced manufacturing. This involves the use of both arc plasma energy sources and laser beam to deposit thin film of a substance on a target. Powder or wire are typically used as the substrate, and deposition occurs in an inert gas or vacuum. Other energy sources could also be utilized.

Plasma metal deposition, which utilizes a plasma source as a method to deposit metals, is one of most promising direct-energy techniques. The process can be used with wire, powder, and both as a feedstock. It can also produce large, complex components. This process offers a lower machining time and shorter lead times.

This process can be applied for ceramics and polymers as well as metals. Metals are usually used in either wire or powder form.

FAQ

How can manufacturing avoid production bottlenecks

Production bottlenecks can be avoided by ensuring that processes are running smoothly during the entire production process, starting with the receipt of an order and ending when the product ships.

This includes both quality control and capacity planning.

Continuous improvement techniques like Six Sigma are the best way to achieve this.

Six Sigma Management System is a method to increase quality and reduce waste throughout your organization.

It's all about eliminating variation and creating consistency in work.

What does it mean to be a manufacturer?

Manufacturing Industries are those businesses that make products for sale. Consumers are the people who purchase these products. These companies employ many processes to achieve this purpose, such as production and distribution, retailing, management and so on. They produce goods from raw materials by using machines and other machinery. This includes all types and varieties of manufactured goods, such as food items, clothings, building supplies, furnitures, toys, electronics tools, machinery vehicles, pharmaceuticals medical devices, chemicals, among others.

What is the responsibility of a logistics manager?

A logistics manager makes sure that all goods are delivered on-time and in good condition. This is done through his/her expertise and knowledge about the company's product range. He/she should make sure that enough stock is on hand to meet the demands.

How is a production manager different from a producer planner?

The main difference between a production planner and a project manager is that a project manager is usually the person who plans and organizes the entire project, whereas a production planner is mainly involved in the planning stage of the project.

How can efficiency in manufacturing be improved?

First, determine which factors have the greatest impact on production time. We then need to figure out how to improve these variables. If you aren't sure where to begin, think about the factors that have the greatest impact on production time. Once you've identified them all, find solutions to each one.

What is the importance of logistics in manufacturing?

Logistics is an integral part of every business. They are essential to any business's success.

Logistics are also important in reducing costs and improving efficiency.

Statistics

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

How to use Lean Manufacturing in the production of goods

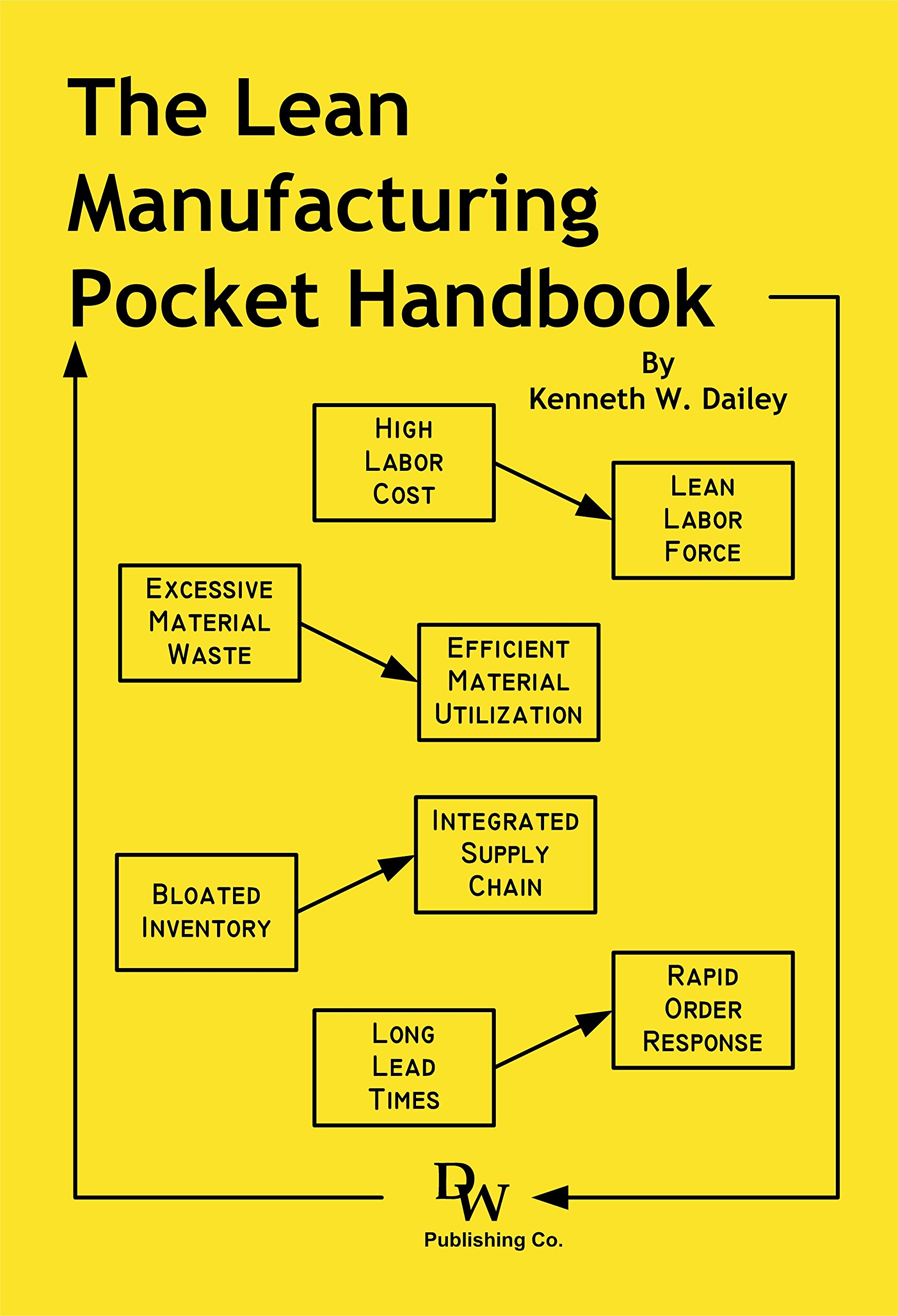

Lean manufacturing is a management style that aims to increase efficiency and reduce waste through continuous improvement. It was first developed in Japan in the 1970s/80s by Taiichi Ahno, who was awarded the Toyota Production System (TPS), award from KanjiToyoda, the founder of TPS. Michael L. Watkins published the original book on lean manufacturing, "The Machine That Changed the World," in 1990.

Lean manufacturing, often described as a set and practice of principles, is aimed at improving the quality, speed, cost, and efficiency of products, services, and other activities. It emphasizes eliminating waste and defects throughout the value stream. The five-steps of Lean Manufacturing are just-in time (JIT), zero defect and total productive maintenance (TPM), as well as 5S. Lean manufacturing is about eliminating activities that do not add value, such as inspection, rework, and waiting.

Lean manufacturing improves product quality and costs. It also helps companies reach their goals quicker and decreases employee turnover. Lean manufacturing is considered one of the most effective ways to manage the entire value chain, including suppliers, customers, distributors, retailers, and employees. Many industries worldwide use lean manufacturing. Toyota's philosophy, for example, is what has enabled it to be successful in electronics, automobiles, medical devices, healthcare and chemical engineering as well as paper and food.

Lean manufacturing includes five basic principles:

-

Define Value- Identify the added value your company brings to society. What makes you stand out from your competitors?

-

Reduce Waste - Remove any activity which doesn't add value to your supply chain.

-

Create Flow - Make sure work runs smoothly without interruptions.

-

Standardize & simplify - Make processes consistent and repeatable.

-

Develop Relationships: Establish personal relationships both with internal and external stakeholders.

Although lean manufacturing has always been around, it is gaining popularity in recent years because of a renewed interest for the economy after 2008's global financial crisis. Many businesses have adopted lean manufacturing techniques to help them become more competitive. In fact, some economists believe that lean manufacturing will be an important factor in economic recovery.

Lean manufacturing is now becoming a common practice in the automotive industry, with many benefits. These include improved customer satisfaction, reduced inventory levels, lower operating costs, increased productivity, and better overall safety.

It can be applied to any aspect of an organisation. This is because it ensures efficiency and effectiveness in all stages of the value chain.

There are three types principally of lean manufacturing:

-

Just-in Time Manufacturing: This lean manufacturing method is commonly called "pull systems." JIT is a method in which components are assembled right at the moment of use, rather than being manufactured ahead of time. This approach is designed to reduce lead times and increase the availability of components. It also reduces inventory.

-

Zero Defects Manufacturing (ZDM): ZDM focuses on ensuring that no defective units leave the manufacturing facility. If a part needs to be fixed during the assembly line, it should be repaired rather than scrapped. This is also true for finished products that require minor repairs before shipping.

-

Continuous Improvement: Continuous Improvement aims to improve efficiency by continually identifying problems and making adjustments to eliminate or minimize waste. Continuous Improvement (CI) involves continuous improvement in processes, people, tools, and infrastructure.