Logistics jobs are among the most exciting and rewarding careers in the world. There are many career options available in logistics, from supply chain management and warehouse management to transportation and logistic operations. There are many opportunities for jobs in Chicago's most vibrant and exciting neighborhoods, such as Uptown and West Loop. However, you also have the option to find work in the suburbs. A logistics job in Chicago could be the right fit for you, whether you're looking for an entry-level position or a career advancement.

There are a number of companies in Chicago that are currently hiring. One of the best is Echo Global Logistics, a leading provider of technology-enabled business process outsourcing (BPO) services. The company's proprietary web-based technology allows clients to achieve significant transportation savings. Additionally, its dedicated service teams work tirelessly to ensure client satisfaction.

Echo Global Logistics offers clients access not only to a strong procurement force, but also a comprehensive suite of service offerings. For example, one of the company's clientele includes a multinational warehouse in Chicago's Bedford Park neighborhood. The warehouse can use its proprietary web-based technology to manage shipments immediately, eliminating long term imbalances and improving customer experience.

Some of the best universities in the country are found in Chicago. Northwestern University, University of Illinois at Chicago and University of Wisconsin Madison are just a few of the most well-respected schools in the state. To complement its excellent academic programs, the city has a number of thriving cultural and entertainment districts. It is possible to see many of city's most iconic landmarks from the Magnificent Mile. There are also the West Loop, Loop, and Gold Coast areas that are popular in the city. These neighborhoods have a number of the most renowned restaurants in the world.

Having a well-rounded education is a must. Even though some people enter logistics without a degree, it's important to have a degree that is relevant to your job. A degree in supply chain management, entrepreneurship, business, or even accounting will certainly help. You may need a degree in these areas depending on what company you work for to secure a high-paying job. Online degree programs offer both bachelor and masters-level courses if you aren't able to afford a full time MBA program.

To learn more about a career as a logistics professional, visit the company's website. Also, make sure to check out the company's policies and procedures. It will pay off. You'll enjoy a more rewarding and successful career. It will also provide a safe work environment.

With some hard work and a little luck you could also find some of the most desirable jobs in the city. You won't get to the top of this ladder overnight. The location of your job or business requirements may dictate the work hours you have to put in, so it is important that you are flexible.

FAQ

What are the goods of logistics?

Logistics involves the transportation of goods from point A and point B.

They encompass all aspects transport, including packaging and loading, transporting, storage, unloading.

Logisticians make sure that the right product arrives at the right place at the correct time and in safe conditions. They assist companies with their supply chain efficiency through information on demand forecasts. Stock levels, production times, and availability.

They also keep track of shipments in transit, monitor quality standards, perform inventories and order replenishment, coordinate with suppliers and vendors, and provide support services for sales and marketing.

What is the difference between Production Planning and Scheduling?

Production Planning (PP), is the process of deciding what production needs to take place at any given time. Forecasting demand is one way to do this.

Scheduling involves the assignment of dates and times to tasks in order to complete them within the timeframe.

How can manufacturing avoid production bottlenecks

The key to avoiding bottlenecks in production is to keep all processes running smoothly throughout the entire production cycle, from the time you receive an order until the time when the product ships.

This includes both planning for capacity and quality control.

The best way to do this is to use continuous improvement techniques such as Six Sigma.

Six Sigma can be used to improve the quality and decrease waste in all areas of your company.

It's all about eliminating variation and creating consistency in work.

What are the jobs in logistics?

There are many types of jobs in logistics. Here are some examples:

-

Warehouse workers - They load trucks and pallets.

-

Transport drivers - These are people who drive trucks and trailers to transport goods or perform pick-ups.

-

Freight handlers are people who sort and pack freight into warehouses.

-

Inventory managers - These are responsible for overseeing the stock of goods in warehouses.

-

Sales reps are people who sell products to customers.

-

Logistics coordinators - They plan and organize logistics operations.

-

Purchasing agents - They buy goods and services that are necessary for company operations.

-

Customer service representatives - Answer calls and email from customers.

-

Ship clerks - They issue bills and process shipping orders.

-

Order fillers: They fill orders based off what has been ordered and shipped.

-

Quality control inspectors – They inspect incoming and outgoing products to ensure that there are no defects.

-

Others - There is a variety of other jobs in logistics. These include transportation supervisors and cargo specialists.

What skills are required to be a production manager?

Being a production planner is not easy. You need to be organized and flexible. Effective communication with clients and colleagues is essential.

Statistics

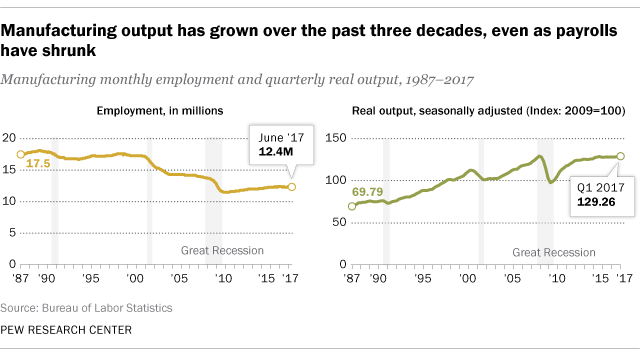

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

External Links

How To

Six Sigma: How to Use it in Manufacturing

Six Sigma refers to "the application and control of statistical processes (SPC) techniques in order to achieve continuous improvement." It was developed by Motorola's Quality Improvement Department at their plant in Tokyo, Japan, in 1986. Six Sigma is a method to improve quality through standardization and elimination of defects. In recent years, many companies have adopted this method because they believe there is no such thing as perfect products or services. Six Sigma seeks to reduce variation between the mean production value. You can calculate the percentage of deviation from the norm by taking a sample of your product and comparing it to the average. If there is a significant deviation from the norm, you will know that something needs to change.

Understanding the dynamics of variability within your business is the first step in Six Sigma. Once you have a good understanding of the basics, you can identify potential sources of variation. Also, you will need to identify the sources of variation. Random variations happen when people make errors; systematic variations are caused externally. For example, if you're making widgets, and some of them fall off the assembly line, those would be considered random variations. You might notice that your widgets always fall apart at the same place every time you put them together.

Once you've identified where the problems lie, you'll want to design solutions to eliminate those problems. The solution could involve changing how you do things, or redesigning your entire process. Once you have implemented the changes, it is important to test them again to ensure they work. If they don’t work, you’ll need to go back and rework the plan.