Until recently, "Made in Japan” meant low-quality consumer goods. Japanese products are known for their reliability, precision and durability. Japanese manufacturers are also setting higher standards. This has increased cost pressure and created more competition. Japanese companies are also being asked how fast they can adapt to changing market conditions.

Japanese factories are known for their high levels of process control. They have control over the work content, labor and working relationships. They do this by training their workers to produce high-quality goods. They also encourage feedback from customers, quality inspectors, vendors, and other stakeholders.

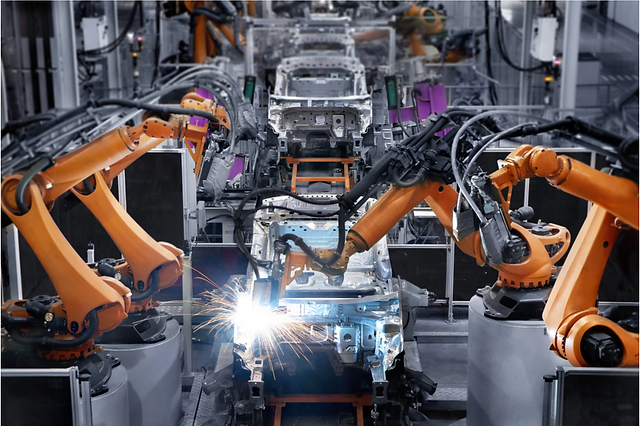

Japan's manufacturing tradition is rooted in Japan's culture of discipline and cultural conformity. Modern technology has also influenced it. Artificial intelligence is used by some Japanese companies to enhance their non-manufacturing workforce. The next generation of technology promises further enhancements to non-manufacturing labor. This includes robots which will work in factories as well nursing homes, hospitals and temples.

There have also been several safety scandals. One case involved a girl aged 13 who died in her factory after contracting a severe illness. Another case involved a company which admitted to having improper vehicle inspection protocols. These scandals have placed the Japanese factory floor under investigation. A number of workers' strikes also changed the working environment. As a result, the government introduced new regulations such closed loop management. It isolates workers and prevents them from contracting viruses.

A second important factor that is affecting Japan's industrial sector is the aging population. Japanese birth rates are declining which means that there is a shortage labor. However, there is not enough native labor to meet this demand. To boost Japanese manufacturing, foreign workers are required. However, many factories cannot source supplies. This is causing problems for their supply chain.

Japanese manufacturers are known for working closely together with their suppliers to solve problems. Some Japanese companies even hold seminars for their suppliers, teaching them how to better meet customer requirements. They also check incoming parts for compliance with specifications. They also use advanced technology, such as automatic checkers, to catch defects before they happen.

The best of Japanese manufacturing is evident in many of their products. Japanese automobiles have a reputation for being fuel efficient, durable, and high quality. The Japanese automotive industry is also the largest in the globe. Japan is home to six of the top 10 automakers, including Toyota and Honda. They are known for producing vehicles with higher quality features at a cheaper price.

Industry will also see a significant shift in the future with technology's new wave, especially when it comes to wages. Robots are already replacing field workers in service organizations. These workers report directly to sales or manufacturing managers. The future of automated manufacturing will be more than just Japanese factories. Robots will be able to work in hospitals or train stations.

Japan faces a variety of challenges in its supply chain. This has affected exports, slowing them down and creating congestion in the port. Another problem is the increase in non-regular labor, which has led to lower standards and reduced costs.

FAQ

What is production planning?

Production Planning includes planning for all aspects related to production. This document ensures that everything is prepared and available when you are ready for shooting. It should also contain information on achieving the best results on set. It should include information about shooting locations, casting lists, crew details, equipment requirements, and shooting schedules.

It is important to first outline the type of film you would like to make. You may have decided where to shoot or even specific locations you want to use. Once you've identified the locations and scenes you want to use, you can begin to plan what elements you need for each scene. For example, you might decide that you need a car but don't know exactly what model you want. To narrow your options, you can search online for available models.

After you have chosen the right car, you will be able to begin thinking about accessories. Are you looking for people to sit in the front seats? Or perhaps you need someone walking around the back of the car? Maybe you want to change the interior color from black to white? These questions will help determine the look and feel you want for your car. You can also think about the type of shots you want to get. What type of shots will you choose? Maybe you want the engine or the steering wheels to be shown. These details will help identify the exact car you wish to film.

Once you have determined all of the above, you can move on to creating a schedule. A schedule will tell you when you need to start shooting and when you need to finish. The schedule will show you when to get there, what time to leave, and when to return home. Everyone will know what they need and when. You can also make sure to book extra staff in advance if you have to hire them. It's not worth paying someone to show up if you haven't told him.

It is important to calculate the amount of filming days when you are creating your schedule. Some projects are quick and easy, while others take weeks. It is important to consider whether you require more than one photo per day when you create your schedule. Multiplying takes in the same area will result both in increased costs and a longer time. You can't be certain if you will need multiple takes so it is better not to shoot too many.

Budget setting is an important part of production planning. As it will allow you and your team to work within your financial means, setting a realistic budget is crucial. Remember that you can always reduce the budget later on if you run into unforeseen problems. You shouldn't underestimate the amount you'll spend. If you underestimate how much something costs, you'll have less money to pay for other items.

Production planning is a very detailed process, but once you understand how everything works together, it becomes easier to plan future projects.

Is it necessary to be familiar with Manufacturing Processes before we learn about Logistics.

No. You don't have to know about manufacturing processes before learning about logistics. However, knowing about manufacturing processes will definitely give you a better understanding of how logistics works.

What are the requirements to start a logistics business?

A successful logistics business requires a lot more than just knowledge. To communicate effectively with clients and suppliers, you must be able to communicate well. It is important to be able to analyse data and draw conclusions. You must be able manage stress and pressure under pressure. In order to innovate and create new ways to improve efficiency, creativity is essential. To motivate and guide your team towards reaching organizational goals, you must have strong leadership skills.

It is important to be organized and efficient in order to meet tight deadlines.

Why is logistics important for manufacturing?

Logistics are an essential component of any business. They enable you to achieve outstanding results by helping manage product flow from raw materials through to finished goods.

Logistics also play a major role in reducing costs and increasing efficiency.

What are the logistics products?

Logistics involves the transportation of goods from point A and point B.

They include all aspects of transport, including packaging, loading, transporting, unloading, storing, warehousing, inventory management, customer service, distribution, returns, and recycling.

Logisticians ensure that the product is delivered to the correct place, at the right time, and under safe conditions. They help companies manage their supply chain efficiency by providing information on demand forecasts, stock levels, production schedules, and availability of raw materials.

They monitor shipments in transit, ensure quality standards, manage inventories, replenish orders, coordinate with suppliers and other vendors, and offer support services for sales, marketing, and customer service.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

How to use the Just In-Time Production Method

Just-in-time is a way to cut costs and increase efficiency in business processes. It's a way to ensure that you get the right resources at just the right time. This means that only what you use is charged to your account. Frederick Taylor was the first to coin this term. He developed it while working as a foreman during the early 1900s. He noticed that workers were often paid overtime when they had to work late. He then concluded that if he could ensure that workers had enough time to do their job before starting to work, this would improve productivity.

JIT is an acronym that means you need to plan ahead so you don’t waste your money. It is important to look at your entire project from beginning to end and ensure that you have enough resources to handle any issues that may arise. You will have the resources and people to solve any problems you anticipate. This will ensure that you don't spend more money on things that aren't necessary.

There are many JIT methods.

-

Demand-driven: This type of JIT allows you to order the parts/materials required for your project on a regular basis. This will enable you to keep track of how much material is left after you use it. It will also allow you to predict how long it takes to produce more.

-

Inventory-based: This allows you to store the materials necessary for your projects in advance. This allows you to predict how much you can expect to sell.

-

Project-driven: This approach involves setting aside sufficient funds to cover your project's costs. If you know the amount you require, you can buy the materials you need.

-

Resource-based JIT: This type of JIT is most commonly used. You assign certain resources based off demand. For instance, if you have a lot of orders coming in, you'll assign more people to handle them. If there aren't many orders, you will assign fewer people.

-

Cost-based : This is similar in concept to resource-based. But here, you aren't concerned about how many people your company has but how much each individual costs.

-

Price-based: This is similar to cost-based but instead of looking at individual workers' salaries, you look at the total company price.

-

Material-based: This is quite similar to cost-based, but instead of looking at the total cost of the company, you're concerned with how much raw materials you spend on average.

-

Time-based: This is another variation of resource-based JIT. Instead of focusing on how much each employee costs, you focus on how long it takes to complete the project.

-

Quality-based JIT: This is another variation of resource based JIT. Instead of looking at the labor costs and time it takes to make a product, think about its quality.

-

Value-based JIT: This is the latest form of JIT. In this scenario, you're not concerned about how products perform or whether customers expect them to meet their expectations. Instead, you focus on the added value that you provide to your market.

-

Stock-based: This inventory-based approach focuses on how many items are being produced at any one time. It's useful when you want maximum production and minimal inventory.

-

Just-in-time planning (JIT): This is a combination JIT and supply-chain management. It is the process of scheduling components' delivery as soon as they have been ordered. It reduces lead times and improves throughput.