A chemical engineer works in engineering or chemistry. They are responsible for the design and operation of equipment and processes that turn raw materials into products. They are responsible for overseeing all aspects of the production process, from designing plant layouts to operating equipment. No matter what your interest is, a degree in chemical engineering can prove lucrative and rewarding. These are the career opportunities available in chemical engineering. These professionals make a difference in every industry they work in, including food and pharmaceuticals.

Aerospace engineering is the hardest major

You must be extremely disciplined to pursue a career in aerospace engineering. This major leaves little room for college party culture. You'll be required to devote hours studying and working on course-related tasks. It is sometimes called rocket science. Aerospace engineering is the design, construction and research of spacecraft and air. This includes both the aeronautical and astronautical branches. Students will need a substantial mathematical load and fluid dynamics.

Chemical engineering is one of the most straightforward majors

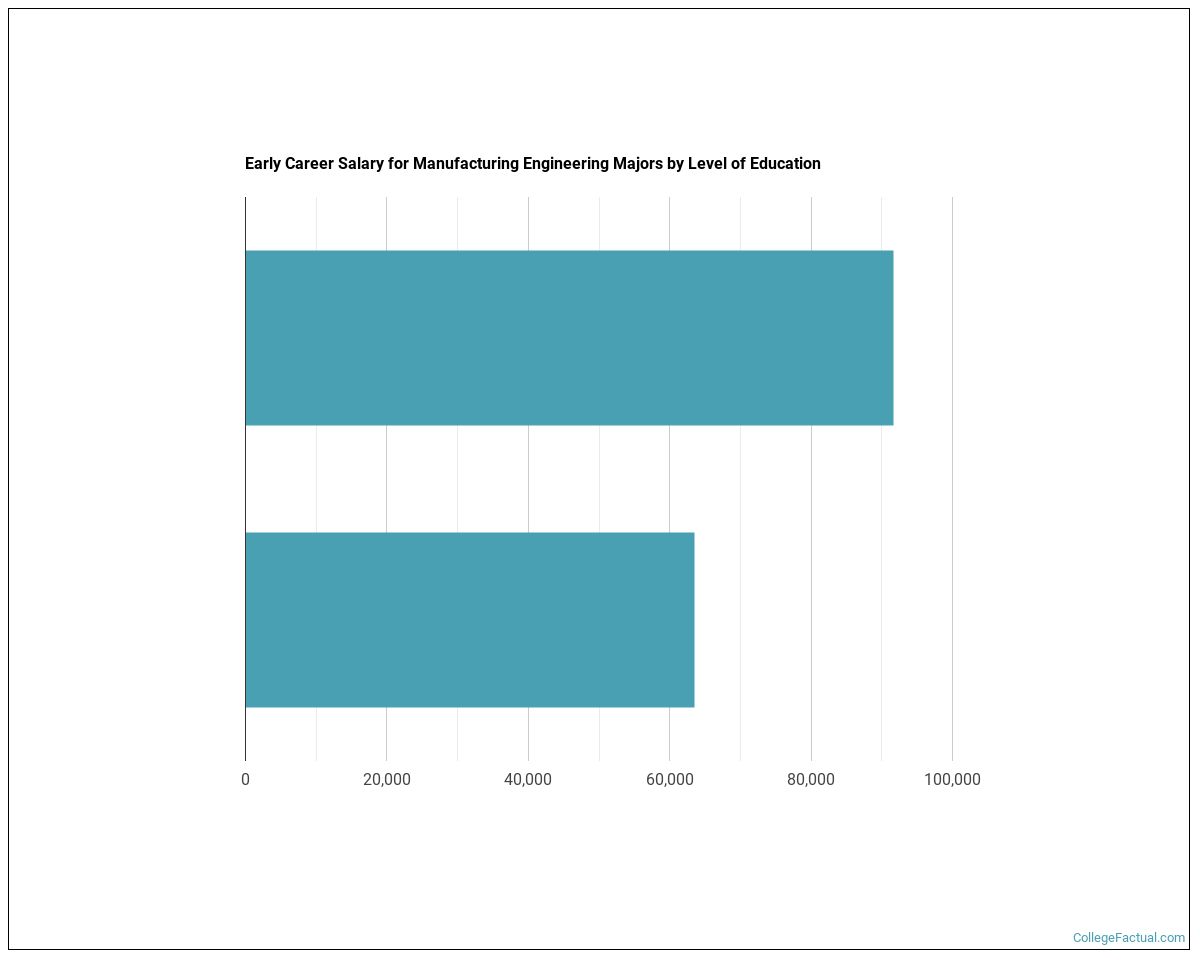

First, you need to have a high grade-point average (GPA), in high school if you want to pursue chemical engineering. Colleges expect that chemical engineering majors will take rigorous coursework in highschool. Taking AP classes is a great way to impress admissions officials. AP classes are a great way to build academic skills. Chemical engineers are well-paid careers with a median salary of $96,300 in 2020.

It requires math and physics.

The majority of undergraduate programs in chemical engineering require 120 to 130 credits. They last for four years. Students will be able to design, build, and analyze chemical products, processes, as well as develop manufacturing equipment. In addition to classroom learning, students in chemical engineering programs take courses in math, physics, and chemistry, and complete internships or cooperative education. Some programs even offer doctoral degrees. A bachelor's degree in chemical engineer is required to be eligible for a PhD.

It is a stable industry

There are many different jobs in the field of chemical engineering. While most chemical engineers work in an office or laboratory, many spend their time on the site where they oversee operations and solve any problems. While they work long hours to meet deadlines. They might also be available at short notice. This field requires knowledge of many complex topics. For instance, a chemical engineer may use computer-aided design software to design the best process.

It pays well

You have many options if you are a recent college grad looking for an entry-level position. An internship is an option if a job has not been advertised. ExxonMobil may have positions open at their company. Engineering, finance operations, operations, and geoscience all have jobs. You can also concentrate on your areas of expertise, such a geophysics, operations, or information tech.

It is a fairly recent subject

Chemistry engineering is fascinating and challenging. You will discover many uses of chemical engineering as a student. Learn about industrial processes that involve complex operations and how they are designed and constructed. You will study unit operations in chemical plants and the implications of changing the variables in a process. Innovative approaches have been employed throughout the history and evolution of chemical engineering to improve student comprehension and participation.

It is a good fit for students who want to be in the field

Chemical engineering is a great choice if you're interested in a career within the chemical industry. Chemical engineering is not only a specialist field, but it also integrates with other disciplines like electrical and mechanical engineering. Chemical engineers are trained to understand and solve problems in the production, use, and transportation of chemicals. Food, fuel, drugs and food are some of the chemicals produced today. You have the option to choose to focus on certain sub-fields, such as environmental and biotechnology, depending on your interests.

FAQ

How can manufacturing efficiency improved?

The first step is to identify the most important factors affecting production time. We must then find ways that we can improve these factors. If you aren't sure where to begin, think about the factors that have the greatest impact on production time. Once you've identified them all, find solutions to each one.

What is production planning?

Production Planning involves developing a plan for all aspects of the production, including scheduling, budgeting, casting, crew, location, equipment, props, etc. This document aims to ensure that everything is planned and ready when you are ready to shoot. This document should also include information on how to get the best result on set. It should include information about shooting locations, casting lists, crew details, equipment requirements, and shooting schedules.

The first step is to decide what you want. You may have already chosen the location you want, or there are locations or sets you prefer. Once you have identified the scenes and locations, you can start to determine which elements are required for each scene. Perhaps you have decided that you need to buy a car but aren't sure which model. In this case, you could start looking up cars online to find out what models are available and then narrow your choices by choosing between different makes and models.

After you have chosen the right car, you will be able to begin thinking about accessories. What about additional seating? You might also need someone to help you get around the back. Maybe you'd like to change the interior from black to a white color. These questions will help guide you in determining the ideal look and feel for your car. It is also worth considering the types of shots that you wish to take. Are you going to be shooting close-ups? Or wide angles? Maybe the engine or steering wheel is what you are looking to film. All of these things will help you identify the exact style of car you want to film.

Once you have established all the details, you can create a schedule. You can create a schedule that will outline when you must start and finish your shoots. A schedule for each day will detail when you should arrive at the location and when you need leave. So everyone is clear about what they need to do. If you need to hire extra staff, you can make sure you book them in advance. There is no point in hiring someone who won't turn up because you didn't let him know.

You will need to factor in the days that you have to film when creating your schedule. Some projects may only take a couple of days, while others could last for weeks. You should consider whether you will need more than one shot per week when creating your schedule. Multiple shots at the same location can increase costs and make it more difficult to complete. It is better to be cautious and take fewer shots than you risk losing money if you are not sure if multiple takes are necessary.

Budgeting is another important aspect of production planning. It is important to set a realistic budget so you can work within your budget. Remember that you can always reduce the budget later on if you run into unforeseen problems. You shouldn't underestimate the amount you'll spend. You'll end up with less money after paying for other things if the cost is underestimated.

Production planning is a detailed process. But, once you understand the workings of everything, it becomes easier for future projects to be planned.

Why is logistics important in manufacturing?

Logistics are an essential part of any business. Logistics can help you achieve amazing results by helping to manage product flow from raw materials to finished products.

Logistics plays a significant role in reducing cost and increasing efficiency.

What are the goods of logistics?

Logistics refers to the movement of goods from one place to another.

They include all aspects of transport, including packaging, loading, transporting, unloading, storing, warehousing, inventory management, customer service, distribution, returns, and recycling.

Logisticians ensure that products reach the right destination at the right moment and under safe conditions. They assist companies with their supply chain efficiency through information on demand forecasts. Stock levels, production times, and availability.

They coordinate with vendors and suppliers, keep track of shipments, monitor quality standards and perform inventory and order replenishment.

Are there ways to automate parts of manufacturing?

Yes! Yes. The Egyptians discovered the wheel thousands and years ago. We now use robots to help us with assembly lines.

Robotics is used in many manufacturing processes today. These include:

-

Automated assembly line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

Manufacturing could also benefit from automation in other ways. For example, 3D printing allows us to make custom products without having to wait for weeks or months to get them manufactured.

Why automate your warehouse?

Automation has become increasingly important in modern warehousing. The rise of e-commerce has led to increased demand for faster delivery times and more efficient processes.

Warehouses should be able adapt quickly to new needs. In order to do this, they need to invest in technology. Automation warehouses can bring many benefits. These are some of the benefits that automation can bring to warehouses:

-

Increases throughput/productivity

-

Reduces errors

-

Increases accuracy

-

Safety enhancements

-

Eliminates bottlenecks

-

Companies can scale up more easily

-

Workers are more productive

-

This gives you visibility into what happens in the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

Reduces downtime and improves uptime

-

You can be sure that high-quality products will arrive on time

-

Removing human error

-

Assure compliance with regulations

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

How to Use Just-In-Time Production

Just-in-time (JIT) is a method that is used to reduce costs and maximize efficiency in business processes. It's the process of obtaining the right amount and timing of resources when you need them. This means that you only pay the amount you actually use. Frederick Taylor developed the concept while working as foreman in early 1900s. He saw how overtime was paid to workers for work that was delayed. He decided that workers would be more productive if they had enough time to complete their work before they started to work.

JIT is an acronym that means you need to plan ahead so you don’t waste your money. You should also look at the entire project from start to finish and make sure that you have sufficient resources available to deal with any problems that arise during the course of your project. You'll be prepared to handle any potential problems if you know in advance. This way, you won't end up paying extra money for things that weren't really necessary.

There are several types of JIT techniques:

-

Demand-driven: This is a type of JIT where you order the parts/materials needed for your project regularly. This will allow to track how much material has been used up. This will allow you to calculate how long it will take to make more.

-

Inventory-based: You stock materials in advance to make your projects easier. This allows you to predict how much you can expect to sell.

-

Project-driven: This method allows you to set aside enough funds for your project. Once you have an idea of how much material you will need, you can purchase the necessary materials.

-

Resource-based: This is the most common form of JIT. You allocate resources based on the demand. You will, for example, assign more staff to deal with large orders. If there aren't many orders, you will assign fewer people.

-

Cost-based: This is the same as resource-based except that you don't care how many people there are but how much each one of them costs.

-

Price-based: This approach is very similar to the cost-based method except that you don't look at individual workers costs but the total cost of the company.

-

Material-based is an alternative to cost-based. Instead of looking at the total cost in the company, this method focuses on the average amount of raw materials that you consume.

-

Time-based: This is another variation of resource-based JIT. Instead of focusing on how much each employee costs, you focus on how long it takes to complete the project.

-

Quality-based JIT: This is another variation of resource based JIT. Instead of focusing on the cost of each worker or how long it takes, think about how high quality your product is.

-

Value-based JIT is the newest form of JIT. In this instance, you are not concerned about the product's performance or meeting customer expectations. Instead, you focus on the added value that you provide to your market.

-

Stock-based: This stock-based method focuses on the actual quantity of products being made at any given time. It is used when production goals are met while inventory is kept to a minimum.

-

Just-intime planning (JIT), is a combination JIT/sales chain management. This refers to the scheduling of the delivery of components as soon after they are ordered. This is important as it reduces lead time and increases throughput.