Industrial management refers to a branch of engineering that integrates various engineering processes into a single management system. An industrial manager helps to integrate these engineering processes into a single, integrated management system. Here are some details about the job. Here are the requirements and benefits of becoming an industrial manager. If you have the required qualifications and are looking for a challenging and rewarding job, this is the career for you. Continue reading for more information.

Job description

An industrial manager is responsible for overseeing the production and manufacturing of goods and services. Although this job covers all aspects of the production process it will also cover how to source raw material and implement equipment. Industrial production managers must be computer literate, as computers increasingly play a key role in the coordination of various departments, suppliers, and clients. In addition, industrial production managers must be well-versed in the latest production technologies and management practices. Many managers attend conferences and trade shows in the industry and also take courses to attain certification.

Industrial managers coordinate the activities in various departments within an organization, and they also oversee manufacturing processes. They ensure that production lines are efficient and meet customer requirements in terms of quality and time. They may also supervise staffing levels or change production levels as required to minimize inventory. They may also be responsible for quality control and coordination with other departments. A majority of this role involves managing people, which includes identifying, training, and motivating employees.

Education Required

A bachelor's degree is not required to be an industrial manager. However, employers will hire those with a background and experience in these fields. Industrial managers also need to be computer literate. Computers are becoming an increasingly important part of manufacturing, helping to coordinate production across departments and suppliers. To excel in this field, interested individuals need to have the right education and experience.

Many industrial production managers start their career as production workers and advance to first-line supervisory positions. All professionals must obtain a college business management degree to reach the industrial manager level. However, there are some workers who can get this education on the jobs. Or they might choose to go to classes sponsored and paid by their company. Most managers will need to have between two and five years of relevant work experience before they are qualified to become managers.

Potential earning

They oversee the smooth operation and management of all manufacturing plants. They decide how to best utilize employees and equipment, meet production standards, and make strategic decisions. Their duties include hiring and evaluating workers, setting production schedules, and ensuring that safety procedures are followed. They also oversee the day-to-day activities of a team of workers and continuously analyze the entire production process to ensure it is operating efficiently and at peak efficiency.

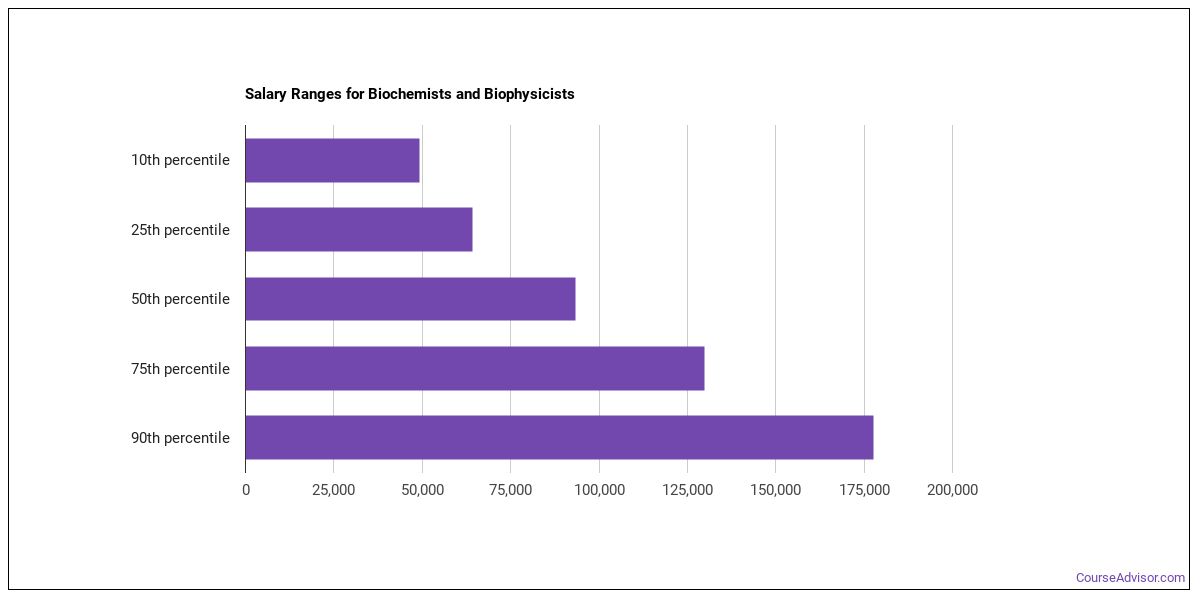

The earnings potential of an industrial production manager depends on the employer and the experience of the employee. It's hard to predict future earnings for industrial managers. The average industrial production manager earned $103,380 annually in May 2016. Industrial production managers with advanced training and certification might earn higher wages. According to the U.S. Bureau of Labor Statistics (USBoLS), industrial production managers who hold a bachelor's or higher degree in manufacturing management may earn more.

Work environment

An industrial production manager splits time between the office and the production floor, sometimes in the same place. When working in production areas, industrial production managers should adhere to established health and safety procedures and wear the appropriate protective equipment. They also spend significant amounts of time in meetings with subordinates and analyzing production data. These managers may also write reports. A manager of industrial production often works in a dynamic environment.

Industrial production managers play an important role in the management of a business. They must coordinate the activities of various workers and increase productivity. A manager of industrial production is responsible for increasing productivity and safety. Due to corporate restructuring, many levels have been eliminated and support staff reduced. Production managers are now able to handle more of the work load. This can be a significant challenge for any manager, and can make it difficult to do the job as a production manager.

FAQ

How can manufacturing avoid production bottlenecks

Production bottlenecks can be avoided by ensuring that processes are running smoothly during the entire production process, starting with the receipt of an order and ending when the product ships.

This includes planning for both capacity requirements and quality control measures.

Continuous improvement techniques such Six Sigma can help you achieve this.

Six Sigma is a management system used to improve quality and reduce waste in every aspect of your organization.

It emphasizes consistency and eliminating variance in your work.

What are the products and services of logistics?

Logistics refers to all activities that involve moving goods from A to B.

These include all aspects related to transport such as packaging, loading and transporting, storing, transporting, unloading and warehousing inventory management, customer service. Distribution, returns, recycling are some of the options.

Logisticians make sure that the right product arrives at the right place at the correct time and in safe conditions. Logisticians assist companies in managing their supply chains by providing information such as demand forecasts, stock levels and production schedules.

They can also track shipments in transit and monitor quality standards.

What is the job of a production plan?

Production planners make sure that every aspect of the project is delivered on-time, within budget, and within schedule. They make sure that the product and services meet client expectations.

What are the requirements to start a logistics business?

To run a successful logistics company, you need a lot knowledge and skills. Good communication skills are essential to effectively communicate with your suppliers and clients. You should be able analyse data and draw inferences. You will need to be able handle pressure well and work in stressful situations. In order to innovate and create new ways to improve efficiency, creativity is essential. You need to have strong leadership qualities to motivate team members and direct them towards achieving organizational goals.

To meet tight deadlines, you must also be efficient and organized.

What does the term manufacturing industries mean?

Manufacturing Industries are companies that manufacture products. Consumers are the people who purchase these products. This is accomplished by using a variety of processes, including production, distribution and retailing. They manufacture goods from raw materials using machines and other equipment. This includes all types if manufactured goods.

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

External Links

How To

How to Use the Just In Time Method in Production

Just-in-time (JIT) is a method that is used to reduce costs and maximize efficiency in business processes. It's the process of obtaining the right amount and timing of resources when you need them. This means you only pay what you use. Frederick Taylor developed the concept while working as foreman in early 1900s. He saw how overtime was paid to workers for work that was delayed. He decided that workers would be more productive if they had enough time to complete their work before they started to work.

JIT teaches you to plan ahead and prepare everything so you don’t waste time. Look at your entire project, from start to end. Make sure you have enough resources in place to deal with any unexpected problems. You will have the resources and people to solve any problems you anticipate. This way, you won't end up paying extra money for things that weren't really necessary.

There are several types of JIT techniques:

-

Demand-driven: This JIT is where you place regular orders for the parts/materials that are needed for your project. This will let you track the amount of material left over after you've used it. This will let you know how long it will be to produce more.

-

Inventory-based : You can stock the materials you need in advance. This allows you predict the amount you can expect to sell.

-

Project-driven: This is an approach where you set aside enough funds to cover the cost of your project. If you know the amount you require, you can buy the materials you need.

-

Resource-based JIT: This type of JIT is most commonly used. You assign certain resources based off demand. For example, if there is a lot of work coming in, you will have more people assigned to them. If you don’t have many orders you will assign less people to the work.

-

Cost-based : This is similar in concept to resource-based. But here, you aren't concerned about how many people your company has but how much each individual costs.

-

Price-based: This is a variant of cost-based. However, instead of focusing on the individual workers' costs, this looks at the total price of the company.

-

Material-based - This is a variant of cost-based. But instead of looking at the total company cost, you focus on how much raw material you spend per year.

-

Time-based JIT: This is another variant of resource-based JIT. Instead of focusing only on how much each employee is costing, you should focus on how long it takes to complete your project.

-

Quality-based JIT: Another variation on resource-based JIT. Instead of worrying about the costs of each employee or how long it takes for something to be made, you should think about how quality your product is.

-

Value-based JIT: One of the most recent forms of JIT. In this case, you're not concerned with how well the products perform or whether they meet customer expectations. Instead, your goal is to add value to the market.

-

Stock-based. This method is inventory-based and focuses only on the actual production at any given point. This method is useful when you want to increase production while decreasing inventory.

-

Just-in time (JIT), planning: This is a combination JIT/supply chain management. It's the process of scheduling delivery of components immediately after they are ordered. This is important as it reduces lead time and increases throughput.